مستشفى الدكتور سليمان الحبيب بالرياض – حي الياسمين

واجهة الرياض

أكاديمية الملك فيصل الجوية – المجمعة

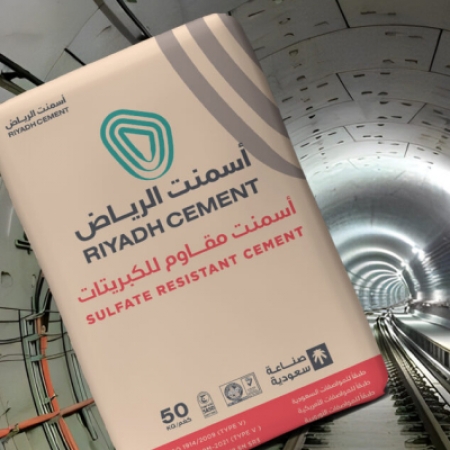

تم إنشاء شركة أسمنت الرياض في عام 1997 وهي من كُبرى شركات الأسمنت في المملكة العربية السعودية، وتتخذ من مدينة الرياض مقراً لها، وتلعب دوراً رئيساً في صناعة الأسمنت بنوعيه الأبيض والأسود عالي الجودة. ومنذ نشأتها قامت الشركة على بعض الركائز والقيم التي تمثل هويتها الوجودية في قطاع صناعة الأسمنت، كالنمو والتطوير المستمر، متخذة "الجودة" وسيلة لتطبيق ركائز الاستدامة، وهو ما جعلها ضمن قائمة أفضل شركات الأسمنت محليا وإقليميا ملبية تطلعات وطموحات العملاء و إمدادهم بالمنتجات النوعية المتميزة لتلبية مشاريعهم المستقبلية.

نلتقي في افاق العربية مع اسمنت الرياض في محطات نجاح متجددة ,سنواصل تحقيق المزيد من الإنجازات المميزة مع اسمنت الرياض

"لقد كنا نتعاون مع شركة أسمنت الرياض في كل مشروع جديد ولا أستطيع تخيل العمل بدونه"

"نحن في مشيد نثمن شراكتنا المستدامة مع مصنع أسمنت الرياض و نشكر أدارة المصنع و الفريق التجاري و فريق الجودة و الشحن بالمصنع على سرعة استجابتهم و حرصهم على جودة المنتجات و خدمة العملاء"

“شراكة استراتيجية صنعت التاريخ، وتُبني اليوم بخطوات ثابتة نحو الرؤية المستقبلية 2030”

![]() المقر الرئيسي: الرياض - المملكة العربية السعودية

المقر الرئيسي: الرياض - المملكة العربية السعودية

طريق الامام سعود بن عبد العزيز بن محمد

![]() ص.ب: 250002 الرياض 11391

ص.ب: 250002 الرياض 11391

![]() البريد: [email protected]

البريد: [email protected]

![]() المبيعات: +966 11 2611888

المبيعات: +966 11 2611888